Pulley diameters calculation

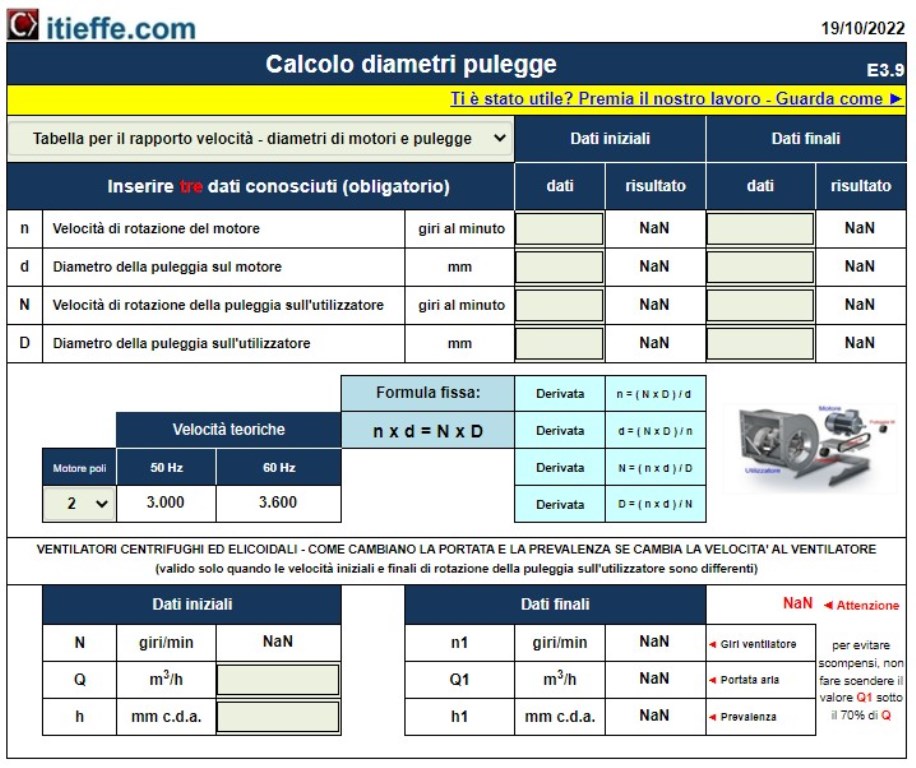

Program to establish the relationship between speed and diameter of the pulleys to allow sizing - Comparable data before and after the modifications - Explanatory summary drawing - The theoretical speeds in rpm based on the motor poles are also indicated.

Welcome to the program created by Itieffe dedicated to the "Calculation of pulley diameters". In a world where power transmission and movement are fundamental elements in a wide range of industrial and mechanical applications, the choice of pulley diameters plays a crucial role in guaranteeing the efficiency and precision of the systems.

This program was created with the aim of providing engineers, designers and mechanical enthusiasts with a complete tool for establishing the relationship between speed and diameter of pulleys and allowing their sizing. Whether you are involved in complex industrial projects or simple mechanical applications, understanding how to select the right pulley diameters is essential for achieving optimum rotational speeds and long-lasting performance.

Regardless of your level of mechanical proficiency, this program will walk you through the essential concepts and calculation procedures necessary to accurately select pulley diameters based on the specific needs of your project. With a solid understanding of these principles, you will be able to design and build drive systems that are reliable, efficient, and accurate.

Remember that the choice of pulley diameters is a crucial step in the design of mechanical transmission systems. With this program, you will be able to face the challenges related to the calculation of pulley diameters competently and to obtain excellent results in any of your mechanical and engineering related undertakings.

Pulley diameters calculation

Developed to establish the relationship between speed and diameter of the pulleys to allow for their sizing.

Comparable data before and after the changes.

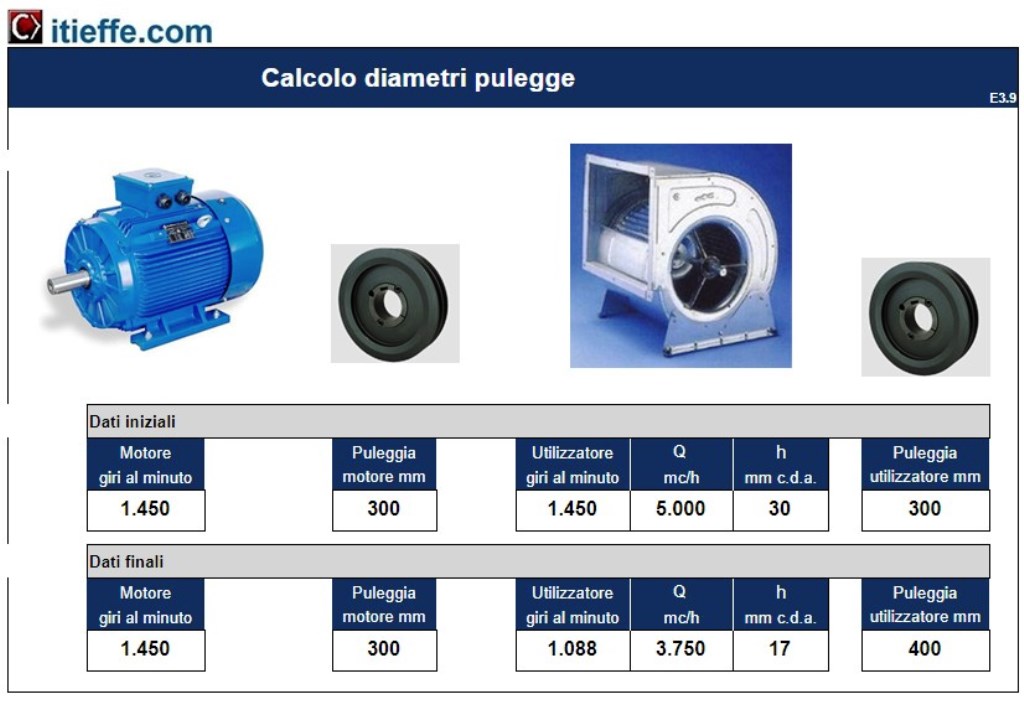

Summary drawing.

Theoretical speeds in rpm are also indicated according to the motor poles.

Complete with instructions

Instructions

Pulley diameters calculation

To those who have had the need to "modify" the air flow (and the prevalence) of an air handling unit or a simple fan with belt drive to increase or decrease the amount of air introduced or extracted from a environment.

Of course, a simple "inverter" could be inserted in command of the motor which obviously has a cost.

Or, a cheaper solution, change the diameter of the transmission pulleys.

The program also calculates the other variables related to the motor / fan coupling.

How to proceed:

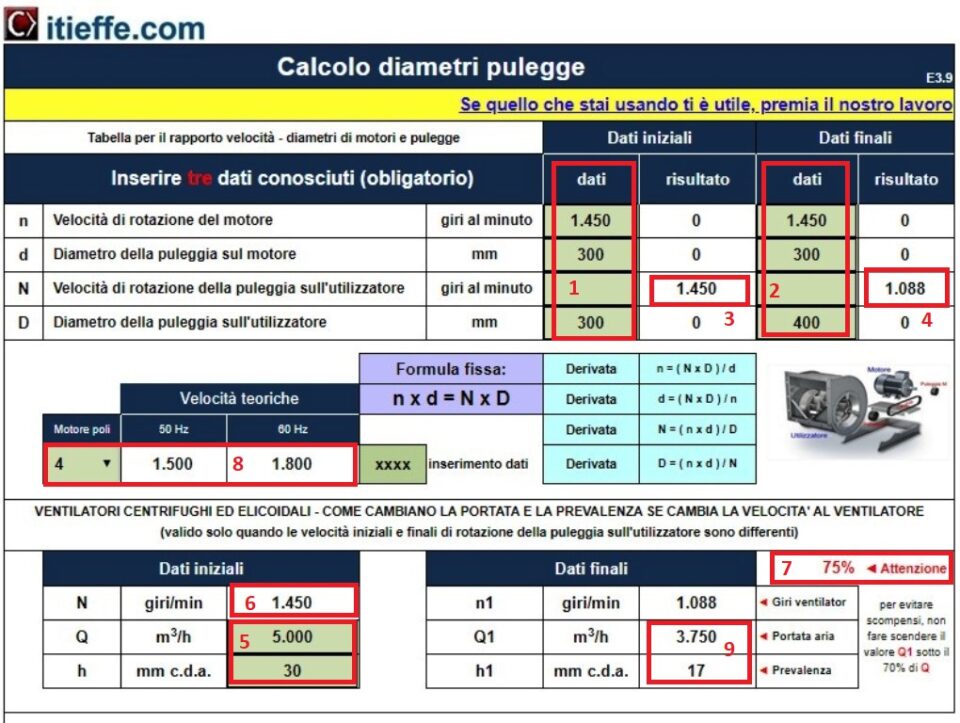

1 - Enter at least three known data in the "Initial data" (1).

2 - Do the same in the "Final data" (2).

3 - At this point the program automatically calculates the missing values (3 and 4).

4 - Now in the part below we insert the initial data of the fan flow rate and head (5). The revolutions per minute (6) in this section have been automatically calculated in the upper part.

5 - Read the results in Final data.

Example

increasing the diameter of the pulley on the user from 300 to 400 mm of a fan with a flow rate of 5.000 m³ / h reduces it up to 3.750 m³ / h (9) and consequently also decreases the head from 30 to 17 mm approx. be careful not to go down beyond the 70% of the initial air flow (7) to avoid imbalances, vice versa, never exceed the value of 100%).

For information, there is the “Theoretical speeds” module which indicates how many revolutions the motor performs per minute, depending on how many poles it is composed of (8).

Finally, view the summary drawing (second part of the report) of the analysis carried out which shows all the calculated values.

Other free programs of the same kind offered by itieffe ▼

- Air conditioning

- Air ducts

- Ventilation systems

- Autonomous air conditioners

- Psychrometric charts

- Air conditioning tables

- Air quality

- Conditioning diagrams & drawings

Pulley diameters calculation

The program below is free to use.

To access the reserved version (see below), full page and without advertising, you must be registered.

You can register now by clicking HERE