General indications on how to design a heat pump complete with references to complete and functioning software. Of excellent help to those who have to make a choice of the type of machine and its correct sizing.

Designing a heat pump is a fascinating process that combines scientific, engineering and practical knowledge to create a highly efficient system capable of exploiting the thermal resources of the surrounding environment to heat or cool living spaces. This guide created by Itieffe was designed to offer a complete and in-depth overview of this crucial topic in the field of thermal engineering and energy efficiency.

Heat pumps represent a sustainable solution for heating and cooling buildings, as they use a minimal amount of electricity to transfer heat from a cold source to a hot one or vice versa. This innovative approach not only reduces energy costs but also helps mitigate environmental impact by reducing greenhouse gas emissions associated with traditional heating and cooling systems.

Purpose of the guide

This guide was created by Itieffe to be a reference point for engineers, designers, students and industry enthusiasts interested in gaining an in-depth understanding of the basic and advanced principles of heat pump design.

We will start with an overview of the main features and components necessary for its operation.

Designing a heat pump is a multidisciplinary process that requires expertise in thermodynamics, fluid dynamics, electrical engineering and more. However, with the right knowledge and guidance, it is possible to tackle this challenge effectively and sustainably.

I hope this guide provides you with a solid foundation to understand and approach heat pump design with confidence and success. Happy reading and good work in the fascinating and increasingly relevant world of heat pumps.

How a heat pump works and how to size it

Wanting to reflect on the technology: "Heat pumps", we note that finally in Italy, all the technicians have started to make calculations in W or kW.

The BTUs (british thermal units) have finally disappeared and this is how it must be seen that in our system (SI) the calculations are strictly in W (or kW).

What is a heat pump

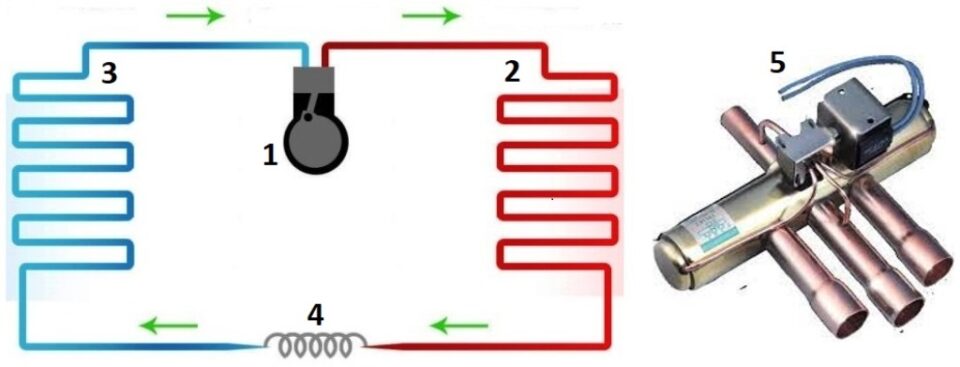

The heat pump is a machine consisting of a closed circuit inside which a refrigerant gas circulates, capable of subtracting heat from one environment to transfer it to another. through the latent heat of evaporation and condensation and through the action of the compressor (keep in mind that there are no machines that produce cold but only those that subtract heat).

In summer, it extracts heat from inside the room via the evaporator and transfers it to the outside via the condenser, causing a lowering of the temperature.

In winter the situation is reversed, the evaporator becomes a condenser and vice versa through a valve (four-way), there will therefore be a subtraction of heat from the outside which will be released into the environment, causing an increase in temperature (see: Refrigeration circuit - The basics).

Performance coefficient

This energy transfer causes the heat pump to multiply the electrical energy used by the system, resulting in a coefficient of performance (COP - Coefficient of Performance) greater than one.

Thanks to its high COP, this technology is therefore the ideal solution able to reconcile costs and energy consumption and environmental sustainability. Each kW absorbed by the machine supplies about 3,5 to the environment (with COP equal to 3,5).

- compressor

- capacitor

- evaporator

- expansion valve (laminator)

- four-way valve

The four-way valve allows the evaporator and the condenser to exchange roles so that in winter the condenser is placed inside the environment, giving it the heat taken from the outside by the evaporator. Conversely, in summer, the condenser releases heat to the outside if the evaporator extracts heat from inside the environment.

There are several varieties of heat pumps that differ from each other in how fluids are exchanged.

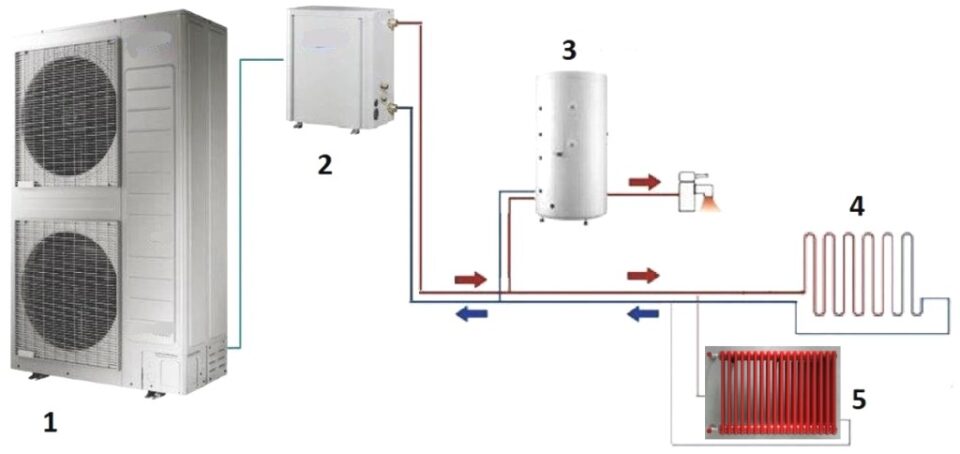

1 - Air-water heat pumps

It is the most common for domestic users. As a source of energy, outside air is used. The heat absorbed from the external air by the evaporator is transferred to the water in the heating circuit.

The optimal external temperature for regular system operation should not be below 2 ÷ 4 ° C.

Below this temperature you will notice variations in the performance of the machine proportional to the temperature itself. The lower the outside temperature, the less the machine will provide acceptable performance.

- heat pump

- hydronic kit

- domestic hot water tank

- radiant floor

- radiators

This type of machine is offered by the manufacturers in various configurations.

At the plant level, there are monobloc and split models that can also be supplied with integrated storage. The most commonly used machine configuration is the split one since being equipped with a hydronic module that can be installed on the wall inside the home, it allows to minimize the external part.

In terms of performance, there are standard models, for harsh climates, and for high temperature water.

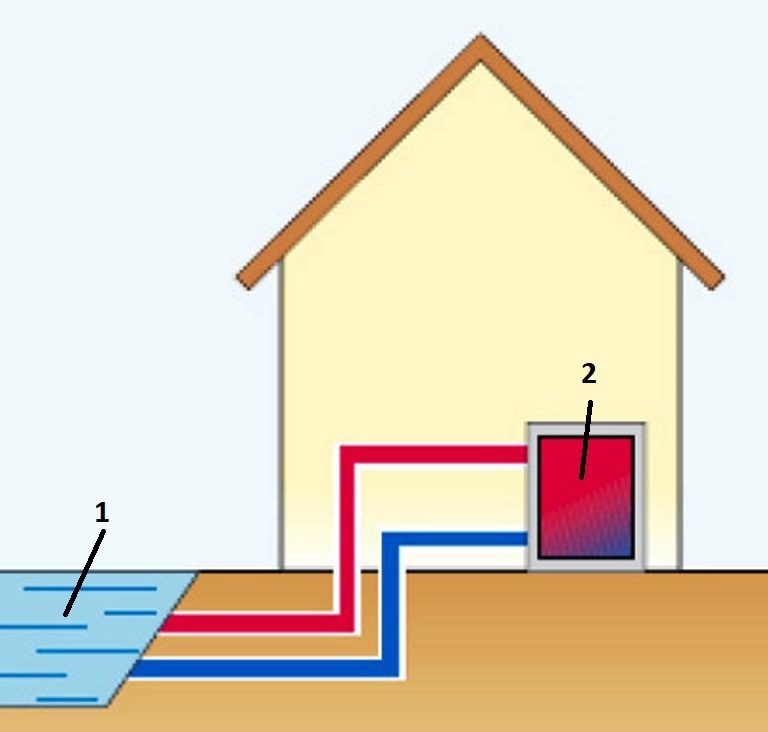

2 - Water-water heat pumps

Water is used as an energy source. The one coming from wells or from groundwater can be used.

The water maintains a stable temperature throughout the year (its temperature is always far above 4 ° C).

This involves maintaining excellent operating performance of the machine in any season.

- aquifer (or well)

- heat pump

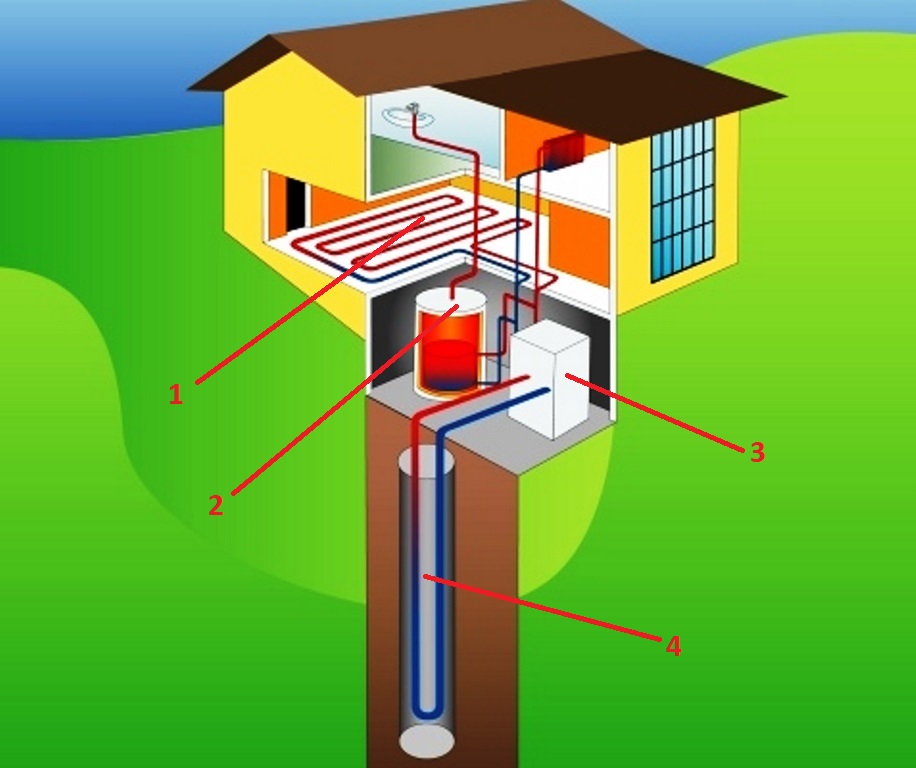

3 - Geothermal heat pumps

Another heat exchange system are the geothermal probes. The ground has its own warmth even in winter.

Using geothermal probes placed in depth it is possible to capture this heat and then transfer it to the water of the heating circuit (obviously through the heat pump).

- radiant floor

- storage tank

- heat pump

- geothermal probe

Which car to choose

To choose the most suitable machine for your needs, the following evaluations must be taken into consideration: type, configuration, size and installation.

1 - Typology

The choice of the type of machine that best suits your needs falls more on the temperature at which it will have to operate, that is, the delivery temperature required by the heating circuit system terminals.

There are machines operating at low or high temperatures on the market. The selection can be made on the basis of the following scheme:

1 - Radiator 2 - Fan coil 3 - Radiant system

Operating temperature 65 ° C Operating temperature 50 ° C Operating temperature 35 ° C

High temperature machine Standard machine or cold climates Standard machine or cold climates

High Temperature Machines

Can be used instead of the boiler in homes equipped with radiators with an operating temperature of around 65 ° C. They allow to keep the distribution and the system terminals unchanged. These machines are capable of producing hot water up to 65 ° C. The COP achieved is quite high. They come to operate with external air temperatures down to -15 ° C.

Standard Machines

Can be used in new installations and for low energy consumption homes. They are able to produce hot water up to 55 ° C reaching high COP values.

Although capable of producing heat with external air temperatures down to -20 ° C, in the case of rigid design temperatures the performance must be checked since below 2 ° C these machines suffer a significant decrease in the performance of power actually delivered.

Cold Climate Machines

Can be used in very cold environments. They are the ideal option to ensure that the heating capacity is maintained even at very low temperatures.

These machines are capable of producing heat with outside air temperatures as low as -28 ° C.

With an external temperature of -20 ° C, they keep the power actually delivered constant without the need for an additional electric superheater.

2 - Configuration

In order to satisfy all plant engineering and installation needs, the heat pumps are produced with different configurations: monobloc, split and tower also called “All in one”.

- Monoblock:

it is the simplest and least invasive to install. It is a single unit that must be installed outside the house, it does not require the creation of connections in the gas circuit, which therefore arrives already complete and tested by the manufacturer, facilitating installation.

A disadvantage to consider is that of having to make the connections of the delivery and return pipes of the hot water outside the house. In the winter season, precautions must be found to avoid the formation of ice when the machine is inoperative.

Heating cables could also be used which, however, actually decrease the performance of the machine as they add up to the electricity consumption of the home.

- Split:

it is the most widespread among those available. Equipped with a compressor to be installed outside the home and a hydronic module to be installed inside.

The internal hydronic module contains the condensation part of the refrigerant and the delivery of the hot water therefore it does not generate any noise as it is without a compressor.

The dimensions are also reduced, allowing installation in the spaces that were previously occupied by the boiler. In this case, however, the installer must make the flow and return connections of the refrigeration circuit between the indoor and outdoor units.

A - condensing unit for heat pump

B - hydronic module

1 ÷ 2 - refrigerant gas flow - return pipe

3 - system and user hot water delivery pipe (winter)

4 - system and user hot water return pipe (winter)

To complete the two systems, there are complete solutions on the market for everything: condensing unit, hydronic module, thermal flywheel (see how to calculate a buffer tank) and domestic hot water storage tank (DHW).

This solution involves a considerable saving in implementation times and a low possibility of making installation errors.

3 - Size

What size should the machine have

Calculation of the nominal heat output

The heat pump must reintegrate the thermal energy dispersed by the complex in order to keep the internal temperature constant.

Three methods are indicated below which can be of help in calculating the most suitable machine size for one's needs, even by those who are not really in the sector.

1 - First method

It is necessary to have precise data to make the calculation.

It starts with the annual thermal energy requirement for winter air conditioning.

- ETH - Annual thermal energy requirement for winter air conditioning: the thermal energy required, during the heating season, for winter air conditioning. Available in the Energy Performance Certificate (APE).

- S - Usable surface: the net walkable surface of the heated rooms of the building net of partitions and external walls, including the thresholds of the doors and the spaces below the system terminals. Available in the house project data.

- gg - Degrees day: the sum of only the positive differences between the internal temperature conventionally set at 20 ° C compared to the external one, during a winter heating period established on the basis of the climatic zone of the location itself. Available in Annex A to Presidential Decree 412/93 and subsequent revisions (see Climatic zones e Indicative country data).

- TEAST - Design external temperature (T2): the minimum external temperature at which the heat generator supplies the thermal energy in any case sufficient to guarantee that the internal temperature remains stationary. The data is available by consulting the UNI 5364 standard and subsequent revisions or the UNI 10339 standard (see External project temperatures).

- h - Daily operating hours: the maximum daily operating hours of the heating (see Climate zones).

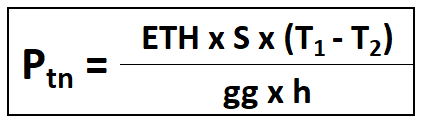

Having obtained these data, it is possible to calculate the nominal heat output of the machine using the following formula:

Where:

Ptn = Nominal heat output of the machine in kW

ETH = Annual thermal energy requirement for winter air conditioning

S = Usable surface in m2

T1 = Internal temperature in ° C

T2 = Outdoor temperature in ° C

gg = Degrees day

h = Hours of operation per day.

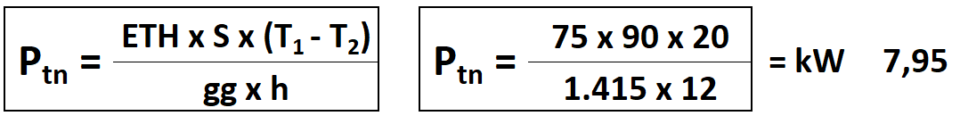

Let's take an example

- Country = Rome (climatic zone D)

- Degrees day = 1415

- Design external temperature = 0 ° C

- Useful surface = 90 m2

- ETH = 75

- h = 12

Applying the formula:

Therefore the nominal useful power of the machine is equal to 7,95 kW

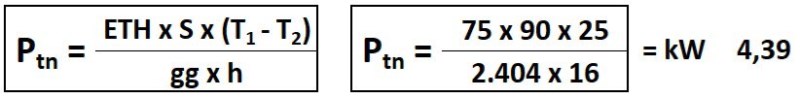

Let's take another example:

- Country = Milan (climatic zone E)

- Degrees day = 2404

- Design external temperature = -5 ° C

- Useful surface = 90 m2

- ETH = 75

- h = 16

Applying the formula:

Although it may seem strange to some, analyzing the data, it is noted that the thermal power that the heat pump must use to maintain optimal temperature values for the same type of environments in two cities with different temperatures, in Rome is equal to 7,95 , 4,39 kW, while in Milan it is equal to XNUMX kW.

To see: "Heat pump sizing - method"

2 - Second method

It is possible to calculate the annual thermal energy requirement for winter air conditioning (ETH) taking into consideration the consumption data indicated in the gas bill.

To carry out this operation, gas consumption must be available for at least the last 4 consecutive years in order to obtain a reliable average consumption.

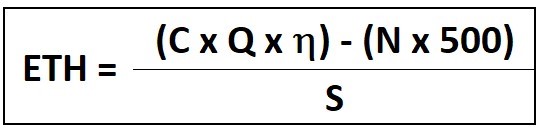

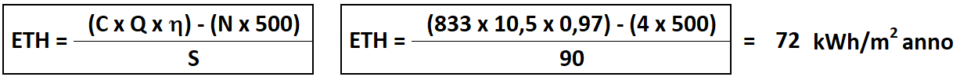

The following formula can be applied:

Where:

ETH = Annual thermal energy requirement for winter air conditioning

C = gas consumption expressed in sm3 (standard cubic meter)

Q = power obtained per sm3 (standard cubic meter) of gas (9,6 kWh for methane and 24,5 kWh for LPG).

- note: LPG is usually purchased in liters. It has a lower calorific value of 12.790 W / kg - 6.500 W / liter and 24.500 W / sm3

η = boiler efficiency (0,82 open chamber - 0,86 sealed chamber - 0,97 condensation).

N = is the number of users for DHW consumption

500 = annual per capita energy consumption for the production of DHW (domestic hot water) expressed in kWh

S = useful surface: net walkable surface of the heated rooms of the building.

Let's take an example

C = 833 sm3

Q = 10,5 kW / h

h = 0,97

N = 4 people

DHW = consumption 500 kW / h

S = 90m2

Applying the formula:

With the ETH value calculated in this way it is possible, using the previous method, to go back to the nominal heat output (P.tn) of the machine expressed in kW.

To see: "Heat pump sizing - method"

3 - Third method

Method that takes into consideration the environmental factors giving as an answer the thermal requirement necessary for each single environment.

More expensive than the previous methods but, in our humble opinion, the most reliable and which extremely indicates the heat requirement divided for each single room.

The times for heating a room are shortened, the set speed is reached first but this obviously involves a greater burden.

The requested value must be entered in each single cell. It is necessary to enter the actual dimensions in width, length and height of each single room, the cardinal exposure, the type of construction, the external temperature. The results can be requested in the indicated units of measurement.

By entering the COP (Coefficient Of Performance) it is also possible to trace the electrical consumption in kW.

The COP is a coefficient of performance and indicates the quality of the machine. The higher its value, the more the machine will provide high performance. In other words, if the COP is equal to 3.5, for each kW of energy absorbed by the machine, it will provide the environment with thermal energy equal to 3,5 kW of which 1 kW of electricity consumed and 2,5 kW taken from the external environment.

The energy efficiency classes of heat pumps according to are indicated in the European directive 2002/31 / EC.

To see: "Heat pump sizing - calculator"

3 - Installation

ACS production

Standard and cold climate heat pumps are designed to operate with refrigerants such as R410 or R32 (see "Refrigerant temperature pressure ratio") for those of the latest generation. They are capable of producing hot water up to 55 ° C and can also be used for the production of domestic hot water. Due to the temperature below 60 ° C they are not able to carry out the thermal disinfection cycles necessary to avoid the possible formation of bacterial colonies (legionella).

It is advisable to use them only for heating and / or cooling (in the case of a reversible machine), leaving the production of DHW to a more specific independent unit, for example a heat pump water heater which, thanks to the use of R134a refrigerant is able to carry out the disinfection cycles.

If, on the other hand, you have a machine for the production of high temperature water operating with R407C refrigerant (or with a specific machine for heating and DHW production by means of a second compression stage with R134a), then it is possible and convenient to maintain all the heat production. within the same unit.

Thermal flywheel accumulation

Even if the heat pump is a modulating machine, it is always advisable to insert a thermal load compensation storage tank (buffer tank or thermal flywheel) in the circuit for the following reasons:

- ensures optimal operating conditions of the heat pump by optimizing the compressor stop - start (on - off) cycles with consequent lowering of consumption.

- allows the connection between different heating circuits.

- it allows hydraulic decoupling between the heat pump and the system so that the two circuits can operate with the most suitable flow rate and temperature differential. Heat pumps usually operate with DT = 5 ° C while, depending on the system terminals present, the distribution circuit could operate with DT even higher.

If the machine is equipped with a scroll compressor (on - off), the inertial storage is mandatory. The typical sizing of the storage volume can be obtained directly from the "Inertial tank calculation”And is a minimum of 5.5 liters per kW of heat output that can be supplied by the machine.

Expansion vessel

The expansion vessel is a "lung" that is connected to the water system; serves to withstand the volume variation caused by the heating / cooling of the water inside the system (see "Mass and volume of water". This eliminates unpleasant problems due to sudden increases in pressure such as: opening of the safety valves or breaking of joints and distribution pipes.

To size an expansion vessel, refer to the program: "Calculation of expansion vessel volume".

To find out the liters of water circulating inside the system, refer to the program: "Calculation of system water volume".

Power supply

For the electrical part of the system, to design the power lines, you can use the program: Sizing of electrical cables - calculator.

To decide whether to adopt a single-phase or three-phase system, refer to the following program: Calculation of power and motor currents

Other free programs of the same kind offered by itieffe ▼

- Air conditioning

- Air ducts

- Ventilation systems

- Autonomous air conditioners

- Psychrometric charts

- Air conditioning tables

- Air quality

- Conditioning diagrams & drawings