Calculation of constant load loss channels

Free program that allows the total sizing of the ducts of an aeraulic circuit using the method based on equal resistance: the duct is proportioned in such a way as to obtain an equal pressure loss due to friction per unit of development of the duct. The free software also allows you to calculate the prevalence of the most unfavorable circuit, the pressure drops in the individual ducts, the surface area and the weight of the ducts. Complete with instructions.

Welcome to the "Constant load loss method air conditioning duct calculation" program. In an era in which energy efficiency and environmental comfort have become priority objectives in the field of air conditioning systems, the accurate design of the air ducts and the management of pressure drops are essential elements to guarantee systems high-performance air conditioning.

The reason for this program

This program, offered by Itieffe, has been developed with the aim of providing an advanced and specialized approach for the calculation and design of galvanized ducts, both quadrangular and circular, used in air conditioning systems. Aimed at HVAC engineers, thermotechnical designers and those involved in plant engineering, the program offers a complete tool for calculating the precise size of the channels starting from the optimal management of the pressure drops.

Through an intuitive and specialized interface and clear examples, you will be able to enter the specific parameters of the air conditioning system and instantly obtain accurate calculations related to the sizing of the ducts made with the "Constant pressure drops" method. This tool will guide you through system performance analysis, duct section selection, and designing efficient and effective air conditioning systems.

We are excited to introduce this program to you, believing it will be a key asset in the HVAC field. Attention to the accuracy of the calculation of the sections of the calculations with the constant head loss method will contribute not only to optimizing the efficiency of the air conditioning systems, but will also guarantee superior room comfort.

We would like to express our gratitude to those who made this program possible and are confident that it will become an indispensable tool for all involved in the design and implementation of high quality air conditioning systems.

Channel sizing method constant pressure drop

Software that allows the total sizing of the ducts of an aeraulic circuit (circular and quadrangular) using the method based on the same resistance: the duct is proportioned so as to obtain an equal loss of pressure due to friction per unit of development of the duct.

The free software also allows you to calculate the prevalence of the most disadvantaged circuit, the pressure drops in the individual ducts, the surface, the weight of the ducts.

Instructions

Calculation of constant load loss channels

The program is fairly intuitive, however the appropriate explanations are given below.

As indicated several times, only the cells with blue characters must be changed.

Below are the indications of the individual cells.

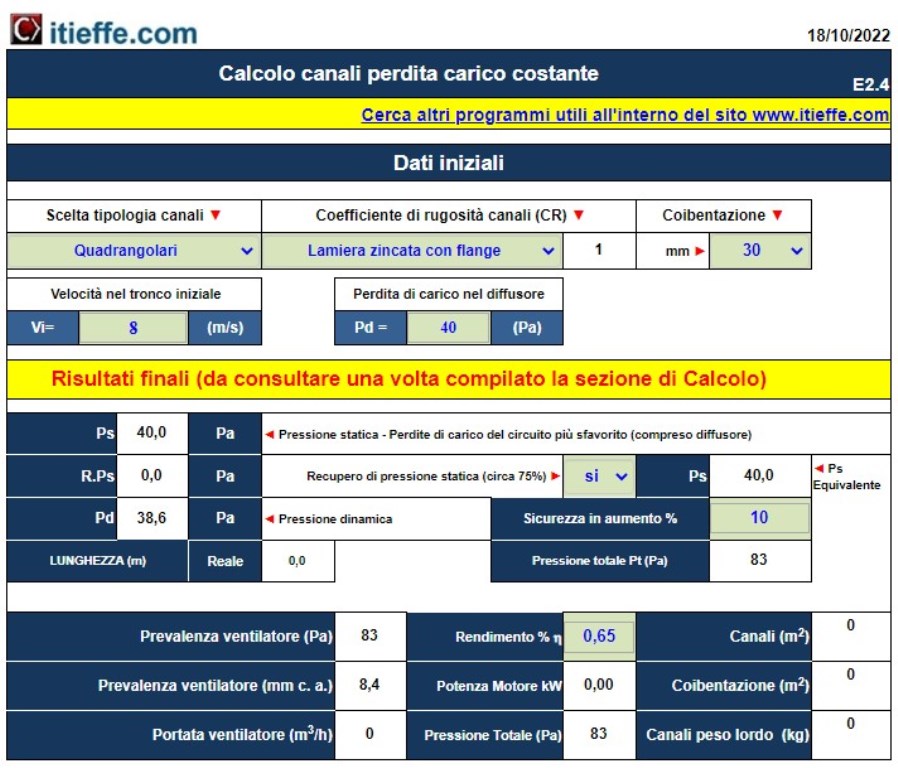

Initial data

Choice of ducts type: choice between circular or quadrangular ducts

CR roughness coefficient: make the choice based on the type of duct used.

Vi = Air speed in the initial log - Enter the chosen speed

Pd pressure drop in the diffuser: enter the value in Pascal found in the tables of the anemostats used

Static pressure recovery - Indicate if pressure is to be recovered

Percent Safety Increasing (%): arbitrary percentage increase in total pressure drop.

Yield%:

- small centrifuges 0,30 0,50

- medium centrifuges 0,50 0,70

- large centrifuges 0,70 0,90

- helical 0,40 0,60

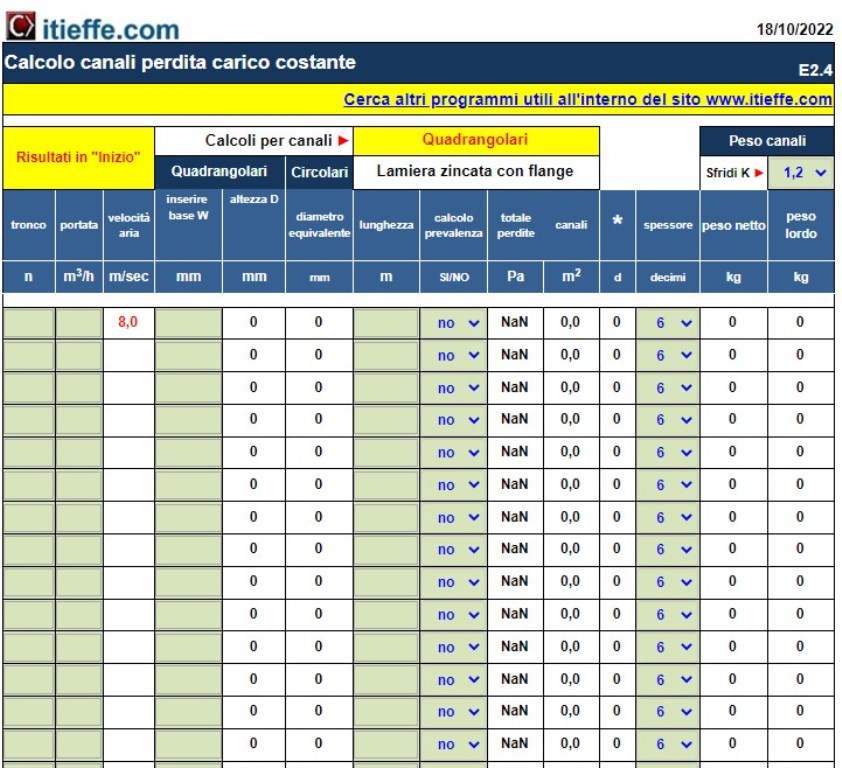

Calculation

Insulation mm: enter the thickness of the insulation - For the return ducting, evaluate whether the insulation is present.

Scraps K: percentage increase in the weight of the ducts due to scraps (material losses)

Trunk: in this column enter the number of the trunk concerned

Flow rate mc / h: enter the air flow rate in this portion of the trunk.

air speed in m / sec: it is calculated automatically, only the first value comes from “Initial data”.

Enter base W (mm): enter the intended base - the height will vary accordingly based on the entered value and vice versa.

Length: enter the length of the log in meters.

Head calculation: enter YES if the section of the section will be used to count the total head of the circuit, NO if the section will not be counted.

Thickness tenths: compare with the previous column and enter the decided value

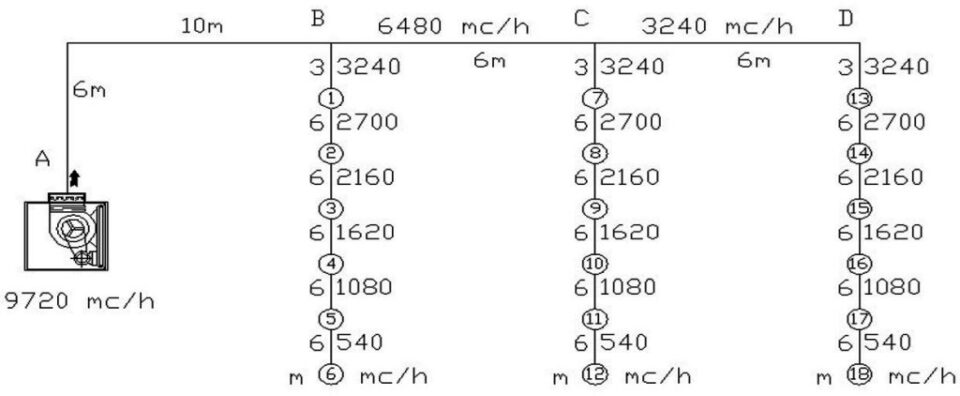

Let's take an example

Let's consider the following scheme

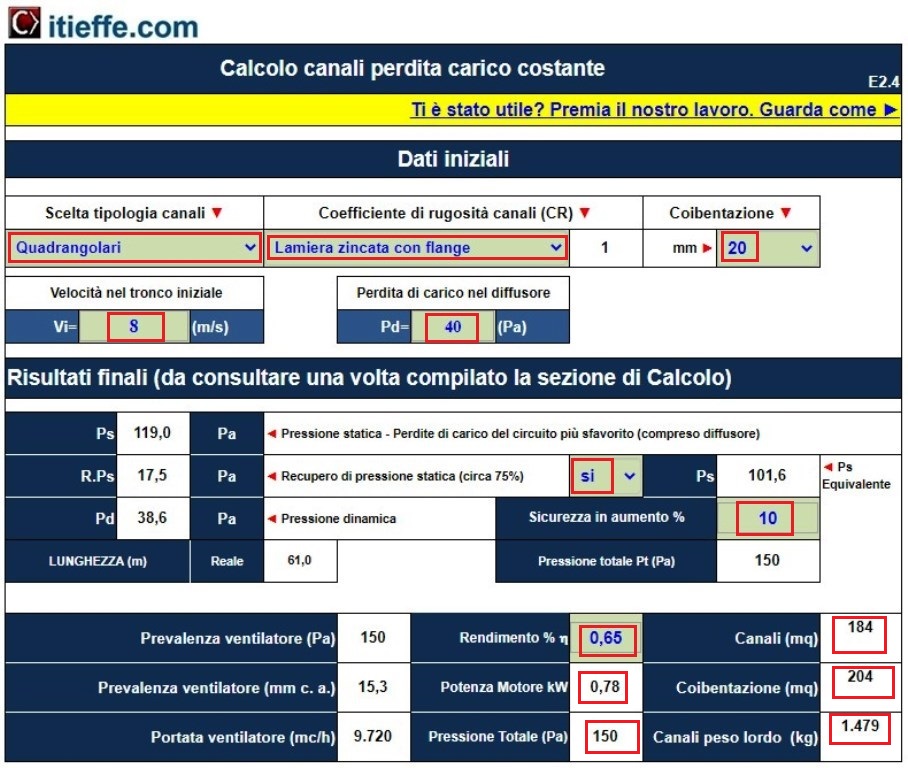

We insert the project data in the boxes highlighted in the first part of the program:

We make the initial choices:

canalizations - quadrangular;

type of ducting - galvanized sheet with flanges (roughness coefficient 1);

insulation 20 mm;

Initial speed - 8 m / s;

pressure drop in the speaker - 40 Pascal;

static pressure recovery - obviously it must always be "yes" but in some cases it is convenient not to recover;

enter a percentage value increasing the pressure (for safety);

we enter the value of the efficiency of the fan motor (0.65).

End of initial data entry.

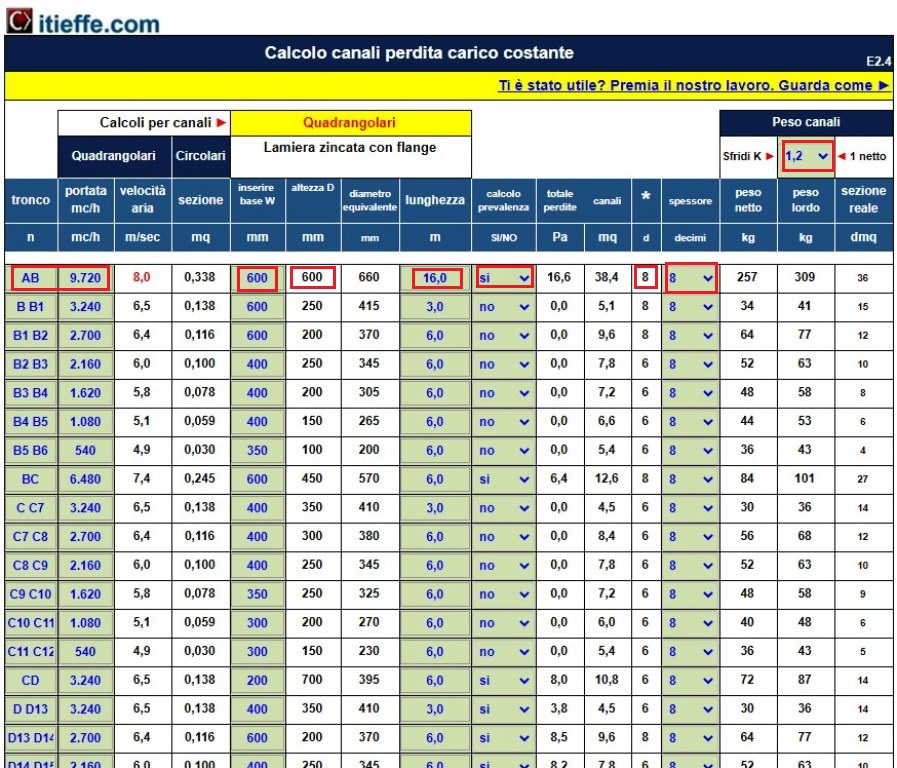

Once this is done, let's report the data coming from the drawing in the second part of the program:

trunk - insert identifier;

flow rates in m³ / h;

quadrangular canal - we insert one side (W) adapting it to the second (D) according to the size (increasing the first the second decreases and vice versa);

length in linear meters of the ducting;

calculation of the trunk head (if "no" is not calculated), through this system, the pressure drops for the most disadvantaged circuit are outlined;

based on the line "*" we give the value to the thickness of the sheet in tenths (only for galvanized sheets).

We insert the "scrap K" - 1.20 (percentage increase in the weight of the ducts due to material losses);

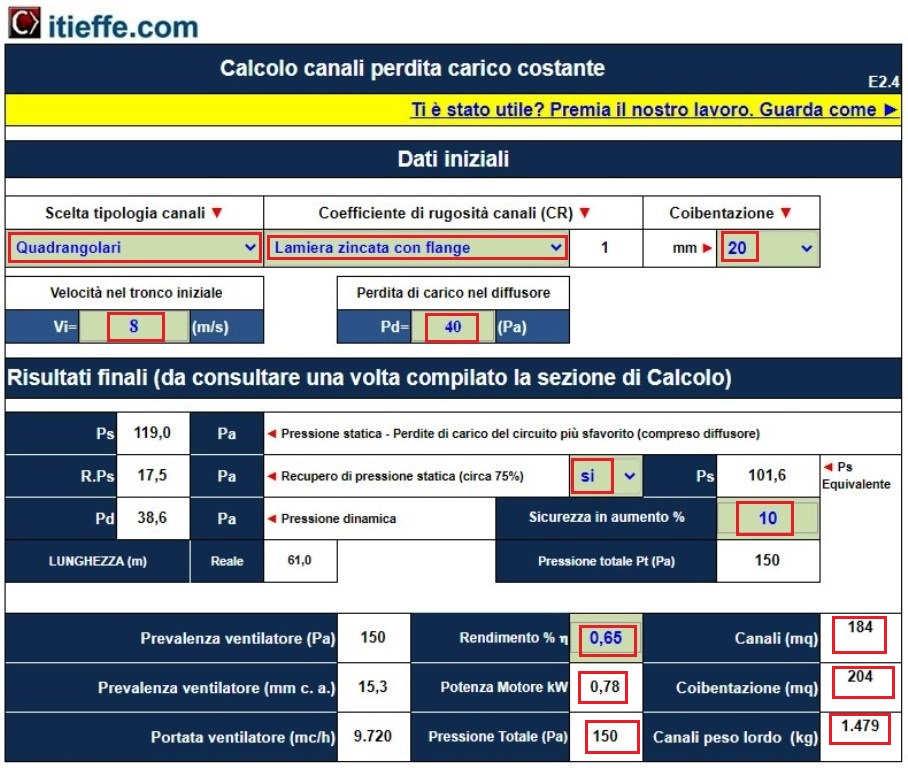

Now let's see the results by returning to the main screen:

total fan pressure - 150 Pa;

motor power - 0.78 kW;

total duct area - 184 m²;

total area of insulation - 204 m²;

total weight of the ducts - 1.479 kg.

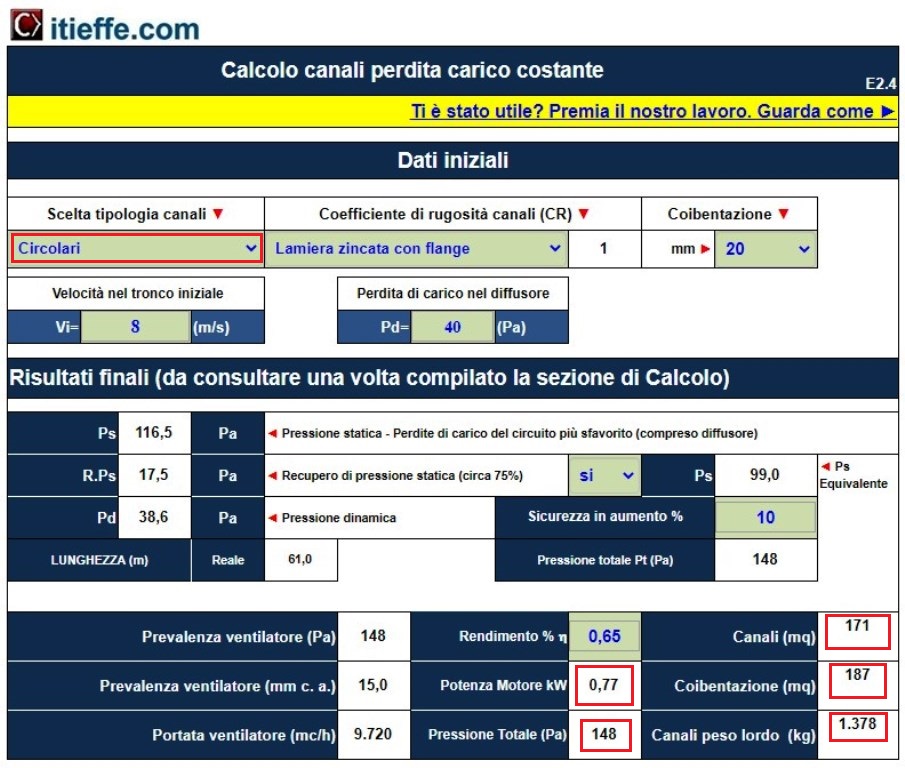

Let's now see the calculation with circular funnel:

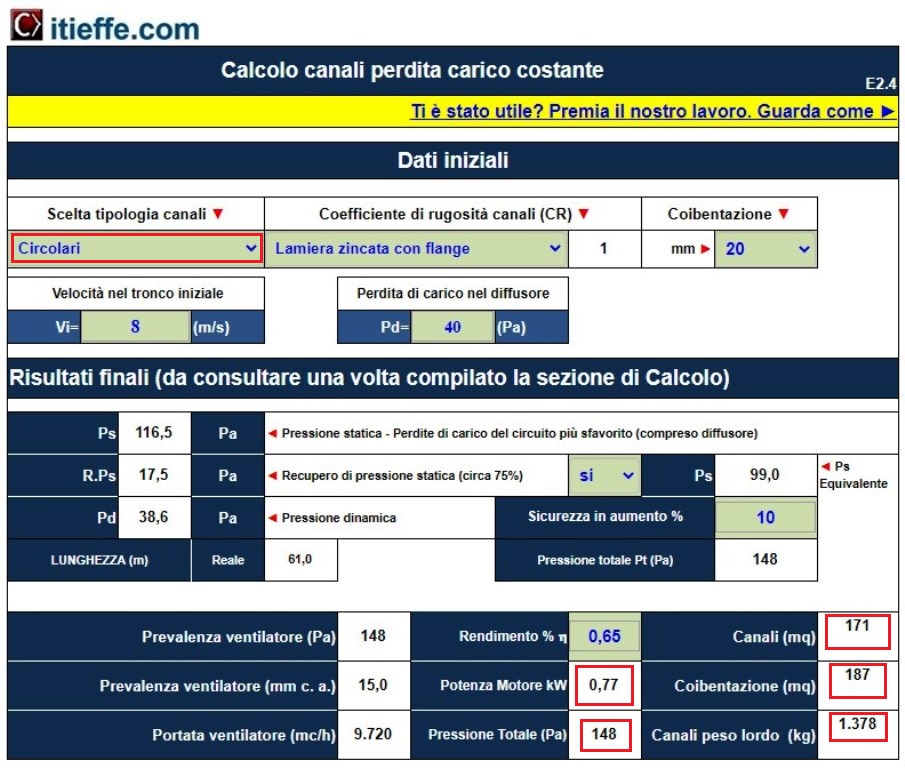

We insert the project data in the boxes highlighted in the first part of the program:

We make the initial choices:

ducts - circular;

type of ducting - galvanized sheet with flanges (roughness coefficient 1);

insulation 20 mm;

Initial speed - 8 m / s;

pressure drop in the speaker - 40 Pascal;

static pressure recovery - obviously it must always be "yes" but in some cases it is convenient not to recover;

enter a percentage value increasing the pressure (for safety);

we enter the value of the efficiency of the fan motor (0.65).

End of initial data entry.

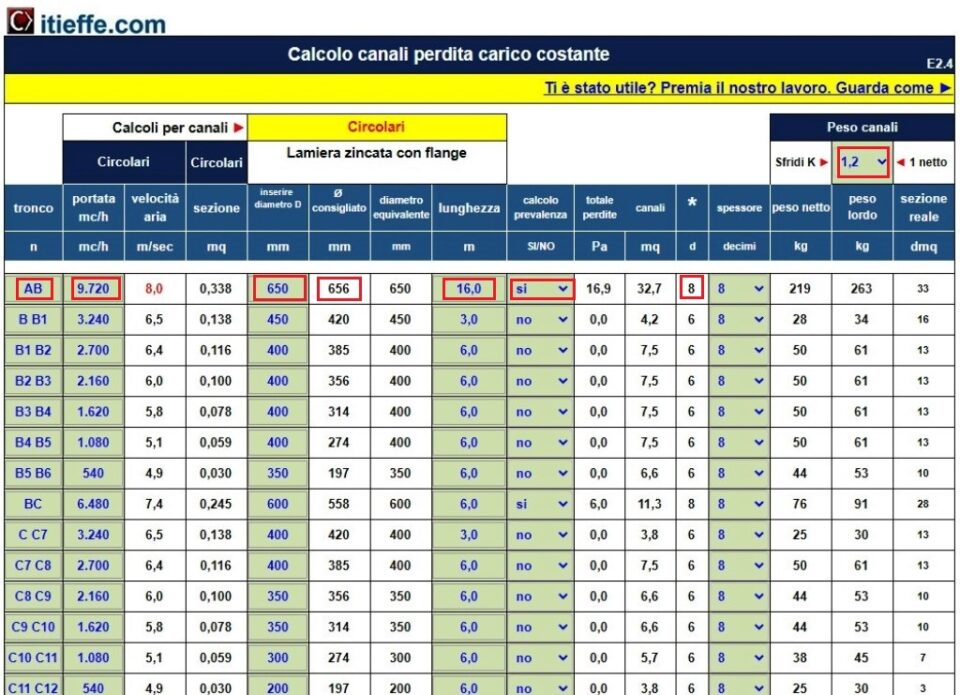

Once this is done, let's report the data coming from the drawing in the second part of the program:

trunk - insert identifier;

flow rates in m³ / h;

circular ducts - let's enter the diameter trying to make it as equal as possible to the “recommended diameter D”, for example taking the first line, the recommended diameter is 656 mm and we choose 650 mm as the real diameter.

length in linear meters of the ducting;

calculation of the trunk head (if "no" is not calculated), through this system, the pressure drops for the most disadvantaged circuit are outlined;

based on the line "*" we give the value to the thickness of the sheet in tenths (only for galvanized sheets).

We insert the "scrap K" - 1.20 (percentage increase in the weight of the ducts due to material losses);

Now let's see the results by returning to the main screen:

total fan pressure - 148 Pa;

motor power - 0.77 kW;

total duct area - 171 m²;

total area of insulation - 187 m²;

total weight of the ducts - 1.378 kg.

Easy?

good job

Other free programs of the same kind offered by itieffe ▼

- Air conditioning

- Air ducts

- Ventilation systems

- Autonomous air conditioners

- Psychrometric charts

- Air conditioning tables

- Air quality

- Conditioning diagrams & drawings

Calculation of constant load loss channels

The program below is free to use.

To access the reserved version (see below), full page and without advertising, you must be registered.

You can register now by clicking HERE