V-belts

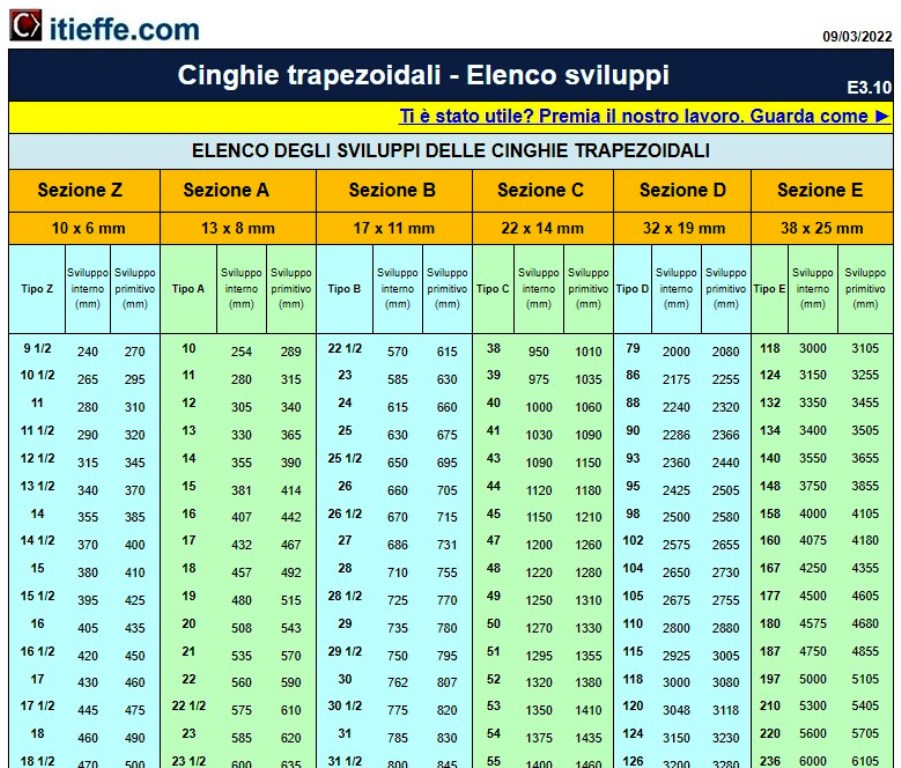

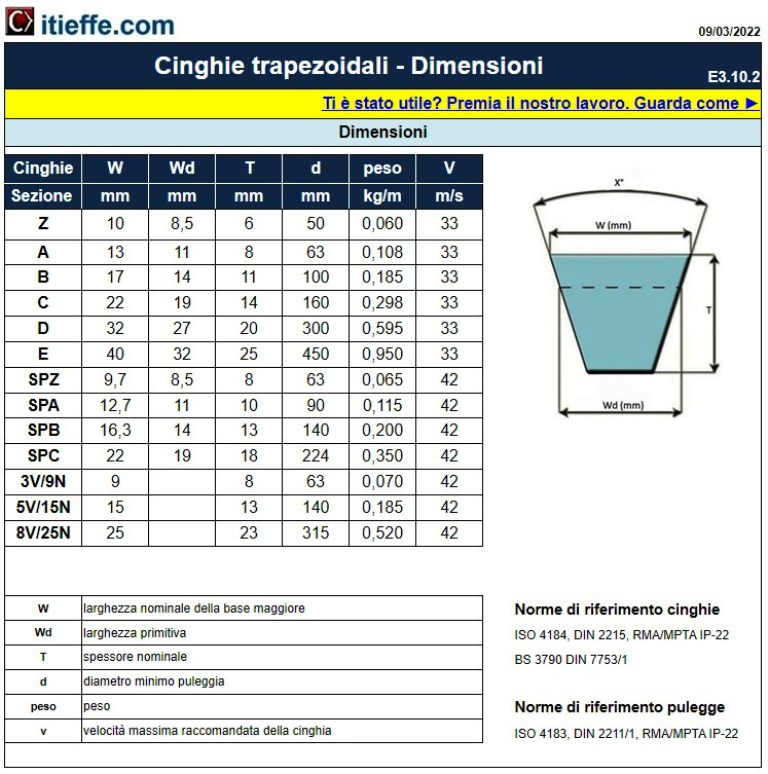

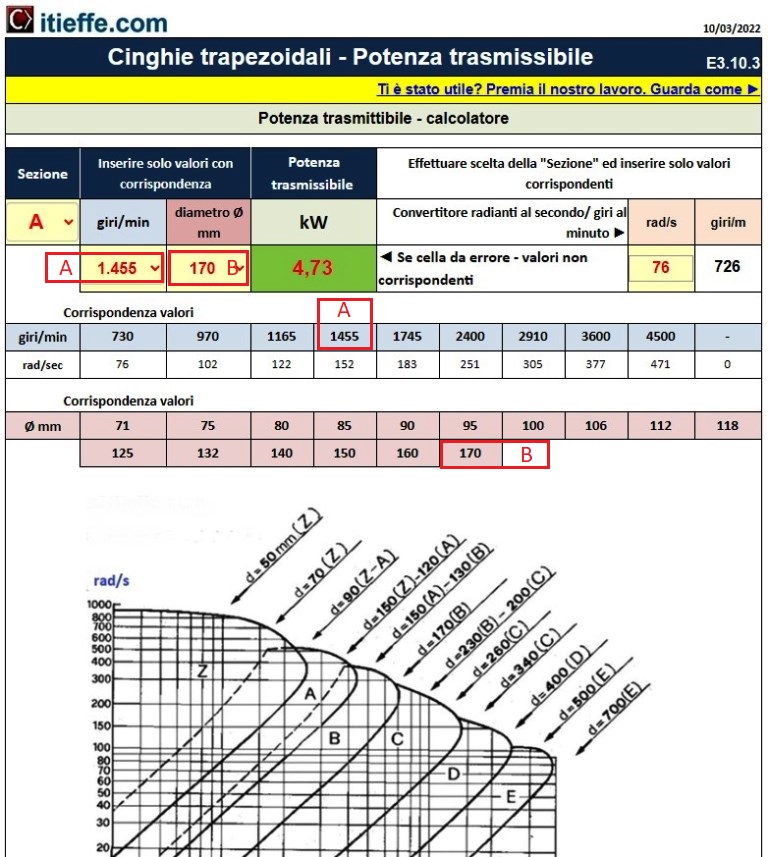

Table indicating the various types of transmission belts and their characteristics, size and transmittable power

V-belts represent a fundamental element in mechanical engineering and power transmission. These components, also known as V-belts due to their trapezoid-shaped cross section, are widely used in a wide range of industrial applications, from machine tools to manufacturing plants, from vehicles to mechanical appliances. Their efficiency and reliability make them a popular choice for transmitting power from one rotating shaft to another.

These documents created by Itieffe focus on three fundamental aspects relating to V-belts:

- List of developments: V-belts have undergone constant modifications and technological improvements over the years. These changes are reflected in the developments currently used. Examining the technological evolution of V-belts is essential to understanding how they have become increasingly efficient and suitable for a wide variety of applications.

- Dimensions:: The dimensions and specifications of V-belts are critical to ensuring proper operation of the power transmission system. These include details on standard belt dimensions, such as width and height, as well as information on belt profiles and tolerances. This data is crucial for selecting and designing V-belts for specific applications.

- Transmissible power: The ability of a V-belt to transmit power is a key factor in the design of transmission systems. This program created by Itieffe, will examine in detail the factors that influence transmittable power, including speed and diameter. Understanding these aspects is essential to ensure reliable and safe design of transmission systems.

Conclusions

In a world where energy efficiency and loss reduction are increasingly important goals, in-depth knowledge of V-belts and their characteristics is crucial. These papers aim to provide detailed and up-to-date information on these components, giving engineers, designers and industrial operators the knowledge necessary to select, use and maintain V-belts optimally in their projects and applications.

V-belts

Indication of the various types of transmission belts, their characteristics and calculator of the transmissible power.

Conventional V-belt is the most common type of V-belt.

They represent the most economical solution for power transmission between two shafts.

The classic V design covers a wide range of sectors: agriculture, ventilation and air conditioning and industrial machinery.

Classic V-belts are capable of covering a load range from some fraction of HP up to 500 HP (372,85 kW).

The general format of the part number is the size of the cross section and the internal length in inches (example: a B50 belt is a B section of 50 inch internal length).

The power transmission between two shafts that may present an axial misalignment is achieved through a system of specially designed belts and pulleys which normally allow even high power to be transmitted.

They allow a uniform and low noise power transmission and in the meantime allow to absorb shocks and sudden load variations, protecting motors and supports.

Machine maintenance

A drive belt requires minimal maintenance and no lubrication, has high misalignment tolerance and high efficiency (95% on average, up to 98%) and its cost does not increase considerably as a function of the distance between the two shafts, as it does. would happen with gear drives.

Furthermore, by acting on the tension of the belt, it is possible to carry out a friction start.

By varying the diameter of the pulley it is possible to obtain different transmission ratios (for example by making conical pulleys).

The field of temperature it usually varies between -30 and 80 ° C.

V-belts are the most widely used for power transmission, while solving the problem of slippage and alignment at the same time.

They offer an excellent compromise between traction, speed, tension on the supports and durability.

The particular shape, housed in the V-groove of the pulley, offers protection against radial slipping, and as the load increases, the drive belt settles more in the hole, consequently increasing friction and improving power transmission.

Speed

The range of speed optimal varies between 5 and 50 m / s.

If the powers involved are high, it is possible to use multiple grooves on the same pulley by inserting several V-belts in the game at the same time.

Other free programs of the same kind offered by itieffe ▼

- Air conditioning

- Air ducts

- Ventilation systems

- Autonomous air conditioners

- Psychrometric charts

- Air conditioning tables

- Air quality

- Conditioning diagrams & drawings

V-belts

The programs listed below are free to use.

To access the reserved versions (see below), full page and without advertising, you must be registered.

You can register now by clicking HERE